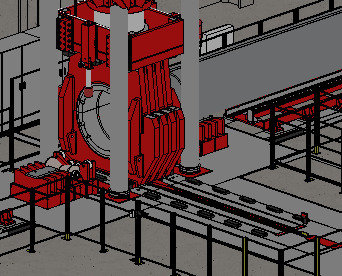

Calibration press

Calibration press for pipes

Automatic hydraulic pipe straightening machine for calibrating and straightening welded pipes.

Hydraulic press for calibrating and straightening pipes after welding and heat treatments, useful for obtaining tubes with the geometric characteristics required by international schedules.

Range: 8-48 inches, thickness up to 80 mm.

Strenghts

Ease of use

High accuracy

.png)

Extreme automation

Technical data

With our state-of-the-art tube straightening machinery, we offer our customers the possibility to calibrate and straighten heavy thicnkness and large diameter pipes.

We distinguish ourselves with our ability to provide highly customized technical data adaptable to our customers' unique needs, ensuring that each customer gets exactly what they need.

High-performance pipe straightening machines for accurate calibration

Our pipe straightening machines are engineered to provide unparalleled precision in the pipe manufacturing process. Designed for use in high-demand production environments, these machines efficiently straighten pipes to ensure they meet the required specifications for further processing.

With robust construction and advanced technology, our pipe straightening machines guarantee exceptional results, improving overall productivity and reducing material waste. Whether you're working with steel, aluminium, or other materials, these machines offer the reliability and durability needed to streamline your pipe production line.

Enhance your pipe production efficiency with our straightening solutions

When it comes to pipe production, a tube straightening machine plays a crucial role in ensuring that each pipe meets the exact tolerances needed for downstream applications. Our calibration press integrates seamlessly with the straightening process, offering a combination of high force and precision to remove deformations and bends from pipes.

This process is essential for producing high-quality, straight pipes that can be used in a wide variety of industrial applications. With a focus on minimizing downtime and maximizing operational efficiency, our straightening machines are a key investment for businesses aiming to enhance their pipe production capabilities.

Plants for pole production

Bending presses and complete plants for processing poles of any height and diameter.

Special applications

Plants made according to specific customer's requirements, equipped with customized equipment and devices.

Our services

We perform spare parts and maintenance services on all types of plants, including ones not built by SOMO

Spare parts

We supply and guarantee original spare parts for every type of machine, from the newest to the oldest. Our sales team is available to guide you to the perfect spare part for your machine.

Revamping

Find out how your machine can be improved by integrating the latest technologies available on the market: a complete renovation of components, mechanical and electronic, and the installation of new management software will give new life to your old SOMO machine.

Maintenance and service

Our technical team is always by your side, even in times of trouble: whether on-site assistance or minor maintenance, you can rely on SOMO.

Remote assistance

Thanks to the remote access setup, in case of breakdown or malfunction, SOMO's technical team will be able to intervene in a timely and accurate manner.

Standards

SOMO machinery complies with the following regulations:

- Machinery 2006/42/EC

- Electromagnetic Compatibility 2004/108/EC.